The world of 3D printing offers a variety of technologies, with Stereolithography (SLA) and Fused Deposition Modeling (FDM) being among the most popular. Both methods have their advantages, but when it comes to speed and efficiency, industrial SLA and industrial DLP 3D printers often outperform traditional FDM systems. Understanding the differences between these technologies is crucial for businesses seeking rapid prototyping and efficient production.

Speed Comparison: SLA vs. FDM

Industrial SLA printers utilize a light source to cure resin layer by layer, allowing for faster production times, especially for complex geometries. The ability to cure an entire layer simultaneously gives SLA technology an edge over FDM, which extrudes material linearly and can be time-consuming when producing intricate designs. Industrial DLP 3D printers, which leverage digital light processing, further enhance this speed by curing entire layers in a single flash, making them even more efficient than traditional SLA methods.

Surface Quality and Detail

Another area where industrial SLA and DLP printers excel is surface quality. The precision of laser scanning in industrial SLA printers results in exceptionally smooth finishes and finer details compared to the typically rougher surfaces produced by FDM machines. This quality is particularly important for industries such as automotive and healthcare, where accuracy and aesthetics are critical.

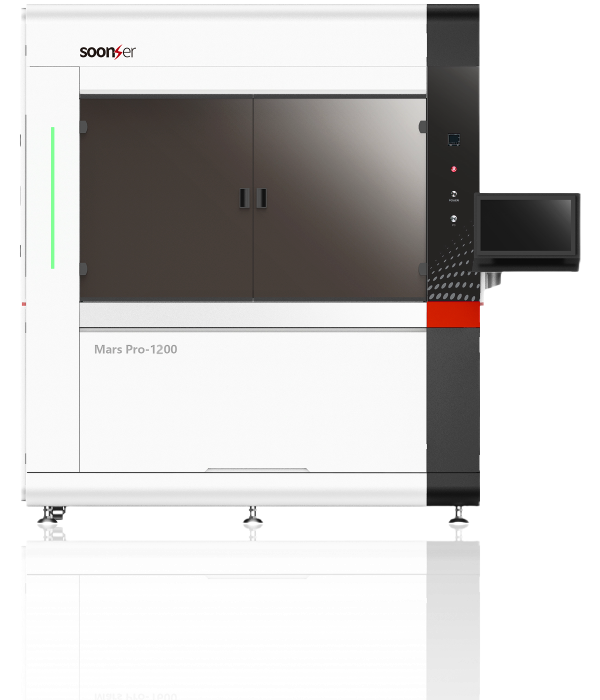

Optimize Production with SoonSer’s Mars Pro Series

For businesses looking to harness the advantages of SLA and DLP printing, the SoonSer Mars Pro Series offers advanced industrial SLA 3D printer solutions that deliver unmatched speed and surface quality. With a large build volume of 1200x700x550mm, the Mars Pro-1200 provides flexibility for scalable production across various applications—from manufacturing to art. Investing in high-performance industrial SLA technology allows companies to accelerate development cycles, optimize operations, and maintain a competitive edge in their respective markets. Embrace the future of 3D printing with SoonSer and unlock new levels of efficiency and precision.