The rapid advancement of artificial intelligence (AI) is revolutionizing the manufacturing landscape, particularly in the production of battery components. Integrated calendering and slitting machines are now leveraging AI technologies to enhance efficiency, quality, and overall productivity. These innovations are crucial as the demand for high-performance batteries continues to soar.

Automation and Precision

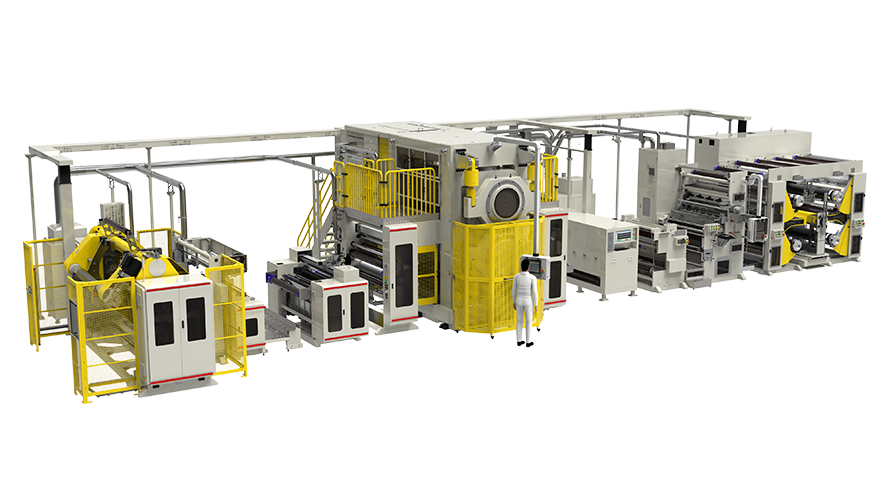

AI-driven integrated calendering and slitting machines automate complex processes that were once manual, significantly reducing human error. With features such as automatic rewinding and unwinding and high-speed online roller cleaning technology, these machines maintain optimal performance. This precision ensures that materials, such as electrode sheets, are processed consistently and accurately, which is essential for achieving high-quality battery performance. By optimizing operational parameters in real-time, AI enhances both speed and accuracy, allowing production rates to reach up to 120 meters per minute.

Enhanced Quality Control

Quality assurance is paramount in battery manufacturing, where even minor defects can have significant implications. AI algorithms can monitor and analyze production data continuously, identifying potential issues before they escalate. This proactive approach allows integrated calendering and slitting machines to perform real-time adjustments, ensuring that every cut made by the electrode slitting machine adheres to strict quality standards. By minimizing waste and maximizing yield, manufacturers can deliver superior products while maintaining customer satisfaction.

Data-Driven Optimization

The integration of AI facilitates data collection and analysis, providing valuable insights into the production process. AI systems can analyze trends, detect anomalies, and recommend adjustments to optimize machine performance. With a maximum roller width of 1.8 meters, the ability to harness this data enables manufacturers to fine-tune operations effectively, resulting in improved output and reduced operational costs. This level of operational intelligence is becoming a critical advantage in the competitive battery market.

Partnering with Yinghe for Advanced Solutions

As manufacturers look to upgrade their production capabilities, investing in AI-powered integrated calendering and slitting machines is essential. Yinghe stands out as a leader in this field, offering state-of-the-art equipment designed to meet the evolving needs of the battery industry. By incorporating cutting-edge AI technology into their machines, Yinghe enables manufacturers to enhance efficiency, improve quality control, and optimize their overall production processes. By choosing Yinghe, companies can stay ahead in the dynamic battery market, ensuring they meet future demands with confidence.