Warehouse management is a crucial aspect of logistics that ensures smooth operations, optimized storage, and efficient order fulfillment. Many businesses consider SAP as a robust solution to streamline their logistics management system. But is SAP itself a warehouse management system (WMS)? In this article, we will explore how SAP works as a warehouse management tool and how it can integrate with automation technologies like SEER Robotics to enhance operational efficiency.

What SAP Offers for Warehouse Management

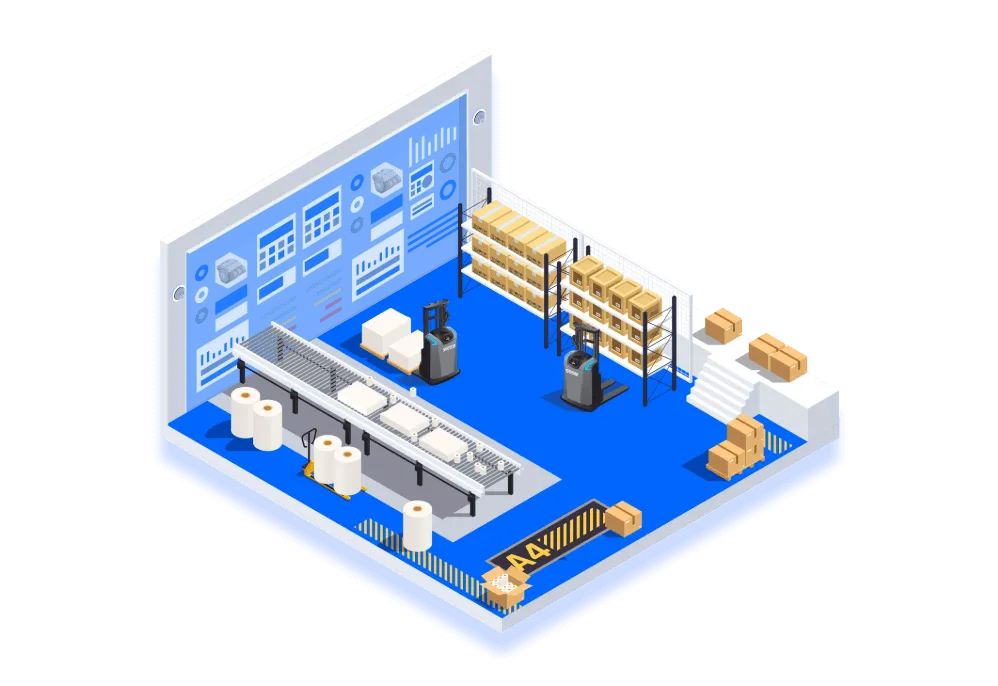

SAP, as a comprehensive business solution, offers a modular approach to managing logistics, inventory, and distribution. The SAP warehouse management system is designed to help businesses streamline their supply chain operations. It integrates core warehouse functions like inventory tracking, order picking, and stock management. By automating key processes, SAP enables real-time visibility into warehouse operations, improving efficiency and reducing errors. It can also support logistics management systems, especially when combined with automation tools like SEER Robotics.

SAP’s warehouse management system provides capabilities for optimizing storage spaces, managing stock movements, and tracking shipments. It works seamlessly with other business processes such as procurement, sales, and distribution, making it an essential tool for enterprises looking to modernize their supply chain.

How SEER Robotics Enhances SAP’s Warehouse Management

The integration of robotics into warehouse operations has transformed logistics management. SEER Robotics, a player in logistics management systems, provides advanced robotic solutions that complement SAP’s warehouse management capabilities. By integrating SEER Robotics into SAP’s warehouse management system, businesses can leverage automation to handle tasks such as material handling, order picking, and packaging. This integration enhances operational efficiency, reduces labor costs, and minimizes human error.

Robots can communicate with the SAP system in real-time, providing continuous updates on inventory levels, order statuses, and task completion. This dynamic flow of information enables businesses to make more informed decisions and adapt quickly to changing demands. Furthermore, with SEER Robotics’s advanced scheduling and task management tools, warehouses can operate more smoothly, even during peak times.

Challenges and Benefits of Using SAP for Warehouse Management

While SAP provides a robust warehouse management system, its implementation can come with challenges. Businesses may face difficulties during the setup phase, particularly when integrating the SAP system with existing warehouse technologies or when customizing workflows to meet specific needs. Additionally, some companies might require a steep learning curve for their staff to become proficient with the system.

Despite these challenges, the benefits of using SAP for warehouse management are significant. The system offers scalability, ensuring it can grow with your business. It also provides improved accuracy in inventory management and enhanced visibility into supply chain activities. When paired with logistics management systems like SEER Robotics, SAP’s capabilities are amplified, resulting in a more efficient and responsive supply chain.

Conclusion

While SAP offers many features typically associated with a warehouse management system, its true value emerges when integrated with cutting-edge automation tools like SEER Robotics. By combining SAP’s comprehensive warehouse management capabilities with the power of robotics, businesses can achieve a streamlined and efficient logistics operation. As the logistics landscape continues to evolve, the integration of logistics management systems and automation will remain crucial for businesses aiming to stay competitive in the market.