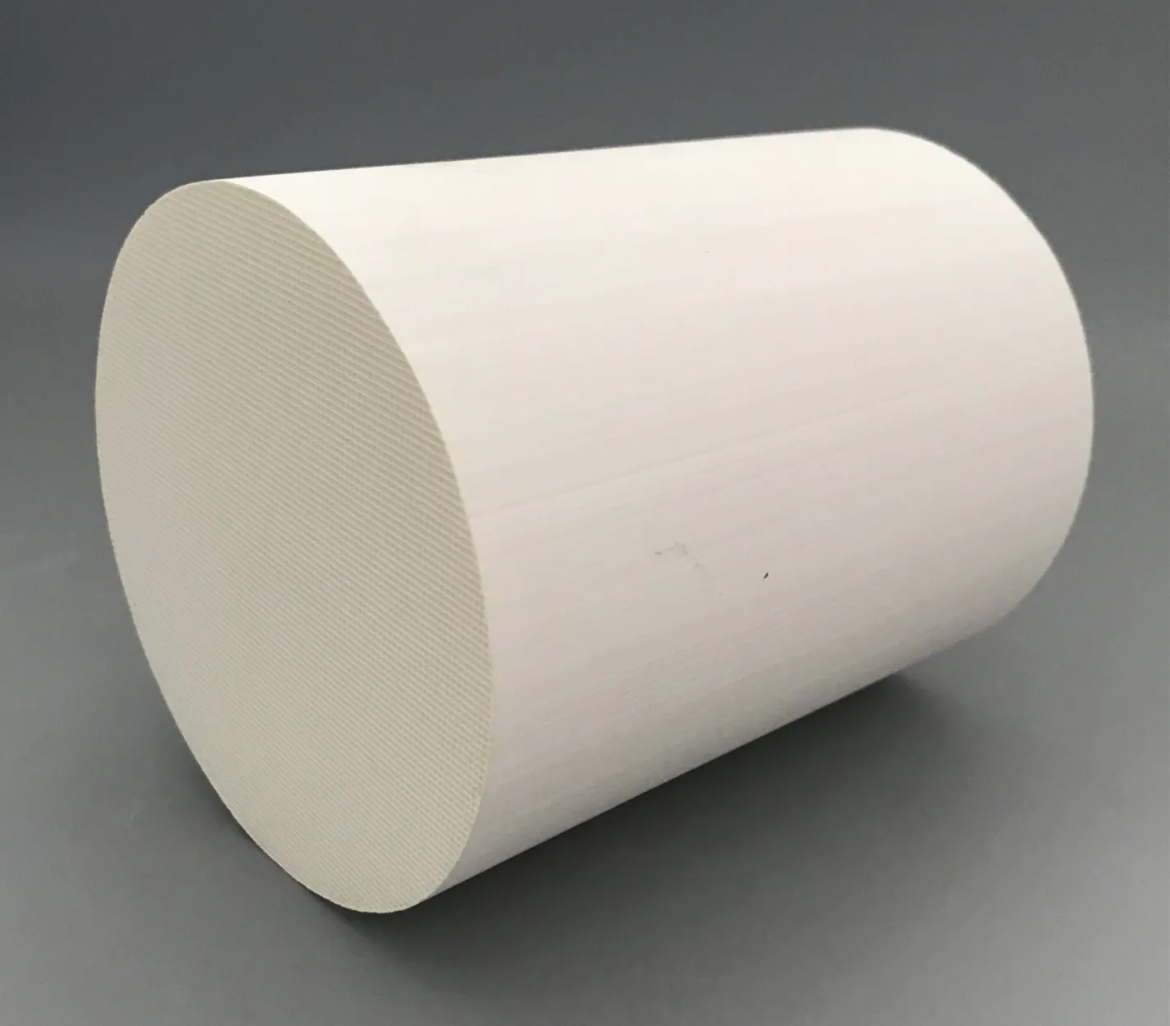

The ceramic catalytic converter is valued for its stable material structure and consistent behavior under high-temperature conditions found in exhaust systems. Built on a porous ceramic base, it maintains uniform flow channels that help promote efficient gas contact with active catalytic coatings. This material feature ensures that exhaust components pass through the converter smoothly without causing unnecessary resistance. When integrating emission solutions into diesel-powered equipment, many experienced users focus on long-term durability and thermal tolerance, and these characteristics directly relate to why ceramic substrates remain widely used. In many projects, they also consider how emission components interact with other treatment devices, including products provided by Hualian Catalyst, as they design complete after-treatment systems.

Structural Advantage of the Honeycomb Configuration

A defining feature of a ceramic catalytic converter is its honeycomb structure, which creates numerous fine channels for exhaust gas distribution. This layout maximizes surface area while keeping the unit compact, ensuring that the catalytic coating is fully utilized during oxidation or conversion reactions. This principle is also reflected in the DOC Catalyst–Honeycomb Ceramic Structure, a diesel oxidation catalyst designed to reduce CO, HC, and SOF emissions. With a durable ceramic substrate, this system supports the conversion of harmful components into CO₂ and H₂O. They offer solutions such as the auto exhaust catalyst, which integrates thermal stability, low pressure drop, and high catalytic activity. These attributes make it suitable for heavy-duty diesel vehicles, construction machinery, and other applications targeting Euro III–VI and EPA compliance.

Application Flexibility and Customization Capabilities

The adaptability of the ceramic catalytic converter is another notable feature. Its structure allows customization of cell density, size, and coating formulation to match regulatory requirements and engine characteristics. For experienced industry users, this flexibility provides room to optimize emission system layouts without compromising engine output or durability. They also provide DOC catalyst products that can be configured according to project needs, allowing for tailored emission performance in non-road and on-road systems.

Conclusion: Why Its Features Matter

In summary, the unique characteristics of ceramic material, the efficiency of the honeycomb structure, and the flexibility in customization collectively define the strengths of the ceramic catalytic converter. These features support reliable emission conversion and help users build systems that balance durability and regulatory demands. They integrate such technologies, including the ceramic catalytic converter and auto exhaust catalyst, into solutions designed for practical, long-term application.